and says “nice weld.” Or something.

Today, I spent a while (about 2 hr) cleaning up the suminigashi bar. I did a bit of subtle shaping to make it bigger at the end where it’s going to support the carbide, but I am not worried about it shattering, bending, or delaminating. As I ground, I had time to let my mind wander and realized that twisting the bar was probably invented as a way to prevent delamination. For one thing, it brings all the surfaces into tight pressured contact, and for another it’s not as though a steel bar is going to un-twist itself: it’s not pasta.

I’m sure it’s not going to shatter, because I gave it a few loving nudges with my hammer to straighten it in spots. I put it in the vise and pushed my whole weight against it and it didn’t even budge: no bounce, no bend. It did not dignify me by noticing me.

That’s where I left it off today. It’s about 1/2″ by 1/2″ more or less – I’ll use a 1/2″ endmill on the bridgeport to cut a channel in the cocobolo to hold the bar. I’m on the fence as to whether or not to hollow some of the back out to fill with lead shot (supposedly dampens vibration) I might just fill the cavity with chopped glass and resin and be done with it.

Before I do that, I need to cut the forward lip for the carbide disk, drill it, and thread it. I may make the forward lip round and pretty using the aforementioned 1/2″ end-mill.

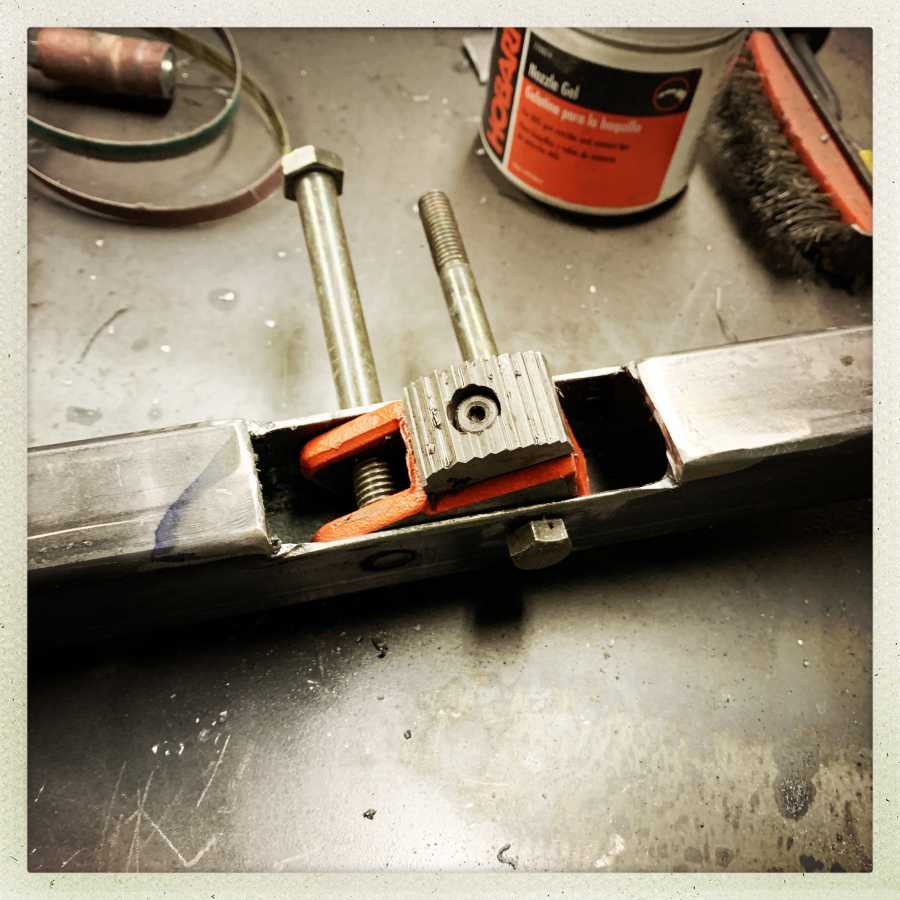

Meanwhile, I’ve been working on another long-running tool build: the twist-o-matic from hell. Most damascus makers use a plumber’s wrench and some weld a bar across the top to serve as a second handle. What I hate about pipe wrenches is that you’ve got to adjust them till they catch, and I don’t like farting around with my fingers that close to a yellow-hot bar of steel. So, I went looking for a quick grab plumber’s wrench, and found just the thing on amazon for $35. It’s a spring-loaded wrench that you just slide on until it locks.

The bandsaw made short work of that. Then, I trued it up a bit with an angle grinder and sanded it clean, ground the circlip off the bolt and disassembled it, measured a piece of 4-foot 14ga tube steel and cut a hole with the diamond wheel.

oh look it’s out of focus!

Well, you get the idea: that piece of tube steel ought not to flex much when I put all my strength on the twist; and 4 feet will give me great mechanical advantage. I ought to be able to grab onto a bar and just walk it around. Best of all, my hands will be 2 feet from the hot thing in the vise.

There was a pause for some excitement:

The old Craftsman angle grinder I keep the diamond wheel mounted on, well, it “crashed and burned.” Literally. I heard a funny screaming noise (in addition to the normal screaming noise of the diamond wheel) and then it stopped suddenly. I assumed it had gotten stuck in the metal somehow, but then smoke and flames started coming out of the air vents of the grinder. How exciting! So I unplugged it and dropped it into the cooling bucket (water) then got another angle grinder out of the closet and finished the cut.

I used a little Chinese-made belt sander that’s powered from the air compressor to reach into the tube and remove all the razor sharp edges of mangling, then sanded, tapped, and rapped things into place.

After that it was off to the milling machine to make some holes. I was worried that I might have positioned the wrench-piece so the arm will jam against the bottom of the bar, but if it does that’s what angle grinders are for. When I had the tube locked into the vise on the bridgeport I realized that I could have just machined the slot in the tube with an end-mill. And it’d have been clean and pretty. If this works like I think it will, I’ll probably have a small line of blacksmiths begging me to make more; I’ll do those on the bridgeport.

Bolts are just visual placeholders; I know those are a bit too long.

Since I was on a roll doing the sloppy-ass machining, I also drilled the center of an old steel hand-wheel, and added a hole for a lock-nut. My bandsaw has a poly/glass handwheel that’s OK but since I use it a lot I may as well make it nice.

I’m still stinging over the bowl gouge, but today went a ways towards making me feel better. The best part was that I was able to shape and finish a couple of handles, and spent some time sanding a bunch of ebony and maple until it was glassy smooth. I have to get those blades to their respective owners before I can post pictures, but they’re work I’m quite proud of. I have an idea for a sort of storage scabbard thing for one of the knives, so I have to give that a try and see if it turns out alright. If it does, you can be sure I’ll be posting it here eventually.

Today is my birthday. Remember, remember, the 5th of November and all that. I’m going to spend the day at the shop doing stuff that needs doing and wednesday I’m going to drive up to Ithaca and smuggle home several dozen bagels (like: 5 doz) from the amazing Ithaca Bakery. They freeze up fine once you know how to reconstitute them, and it’s good to have a supply down in the freezer for the winter.

Happy Birthday!

You are being ridiculously productive.

Happy Birthday!

Happy birthday!

Happy Birthday!

Also, when I first saw the picture of the top half of the plumber’s wrench and the bottom half separated, I thought you had snapped them as you were twisting the bar. Hope you are having fun!

Happy birthday! Enjoy the bagels!

That’s a clever way to solve that problem and yes should be very popular.

James@#4:

Also, when I first saw the picture of the top half of the plumber’s wrench and the bottom half separated, I thought you had snapped them as you were twisting the bar.

One of my favorites on youtube is This Old Tony, who combines machine-shop stuff with a really weird and charming sense of humor. A thing he often does is edit parts of the video into total bullshit. Like, he’ll grab a piece of metal like that wrench, twist it quickly, and it falls into two pieces. It’s funny because it shows how easy it is to produce illusions with even simple video edits. Anyhow, that was what came to mind from your comment: “yeah, I just snapped it off like that.”

I don’t know what plumbers’ wrench bodies are made of but it’s tough stuff. It drilled really nicely, though. Cast iron maybe?

kestrel@#5:

That’s a clever way to solve that problem and yes should be very popular.

When I try it I’ll put a go pro on my head and see if I can record the process. It ought to be dramatic and dizzying.

I just want to keep hopping up and down pointing at the bar and going “I MADE THAT!” It’s currently got a 400grit finish on it but I’ll probably polish it to 1000 grit before I etch it. Then, it’s going to suddenly look crazyamazing. Assuming I didn’t grab the wrong bar.

Congratulations on getting through another year. May many more come!

I thought the same thing as James but then noticed the metal bits sticking out in top of the handle and thought: that looks sawed. And I had the same flame-breating thing, but with a drilling/hammering machine, scary stuff. Maybe powertools want to retire as dragons!

“A blacksmith walks into a bar. And now they clutch their foot and hurl curses, looking for bandages.”

Happy birthday!

It’s great that you are enjoying yourself. Doing your hobby seems like a good way how to spend a birthday (I’m saying this as a person who doesn’t enjoy traditional-style birthday celebrations).

I took a look at the Ridgid website. They make an aluminum version of this wrench, which clearly this is not. The material of this version is simply described as “steel”, so that doesn’t tell us much.

However, the Pipe Wrench Use Guide includes this item, which sort of jumped out at me:

“Do not use near flame or high heat. Teeth on the hook or heel jaw could become soft. This may result in chipping or flattening of the teeth. This reduces its strength which may result in failure.”

And I forgot to mention… happy birthday, Marcus. Many safe and healthy returns. (Happy is up to you.)

Happy birthday!

As far as I know, the handle of that kind of tool is just ordinary mild steel, work-hardened a little by having been squished into that shape. After all, the aluminum version looks exactly the same, so if aluminum alloy is good enough, ordinary mild steel will be more than enough. Definitely no need to break out the chromium-vanadium for the handle. The jaws are definitely a different material. Ridgid describe them as “alloy steel” and “double hardened”, so perhaps there’s some extra manganese there (anything fancier and they would have said more about the alloy, I’d expect).

Happy birthday!

Once upon a time all I could afford was Black & Decker power tools, soon to be dubbed Dead & Blacker. Smoke from them was such a frequent thing.

Enjoy your birthday.

Sorry to be late to the party, but I had to report for potential jury service this morning, and I have been offline all day. Happy Birthday!

a bit late, but happy B-day.

would like to see pics of this when it’s completed, if you are up to posting them.

Happy Birthday, Marcus. I hope you had a good day..

lochaber@#17:

would like to see pics of this when it’s completed, if you are up to posting them.

Me too. I’ll record some video of the thing in action and I’ll post a bit more about the build when it’s done and tested. This has been a fun project.

cvoinescu@#13:

As far as I know, the handle of that kind of tool is just ordinary mild steel, work-hardened a little by having been squished into that shape. After all, the aluminum version looks exactly the same, so if aluminum alloy is good enough, ordinary mild steel will be more than enough. Definitely no need to break out the chromium-vanadium for the handle. The jaws are definitely a different material. Ridgid describe them as “alloy steel” and “double hardened”, so perhaps there’s some extra manganese there (anything fancier and they would have said more about the alloy, I’d expect).

It’s probably mild steel, as you say. What is it they call that, “drop forged”? They have a die and they smash hot metal into it and trim off the excess.

I don’t think the jaws will be a problem – they won’t be in contact with the hot stuff for very long so they shouldn’t transfer too much heat. Most blacksmiths use a normal pipe-wrench, which is basically made of the same stuff. The guys who do a lot of twists usually make a twisting machine – I’ve seen some interesting versions of those, including one (I think it’s Mike Maumasi’s) that has a small forge on little wheels that you can move up and down the bar which is clamped horizontally. You just get the bar hot and keep it hot while you turn a wheel the desired number of times – you can keep the bar at welding temperature and totally go to town on it.

Andreas Avester@#10:

Doing your hobby seems like a good way how to spend a birthday

It was great, but it went by a bit too fast. I suppose if I wanted to have more time to enjoy my birthday I could have sat in a marketing presentation: endless birthday.

Happy belated. Not that it matters, but you share a birthday with two other fantastic people I know. So I always remember the 5th of November. ;)