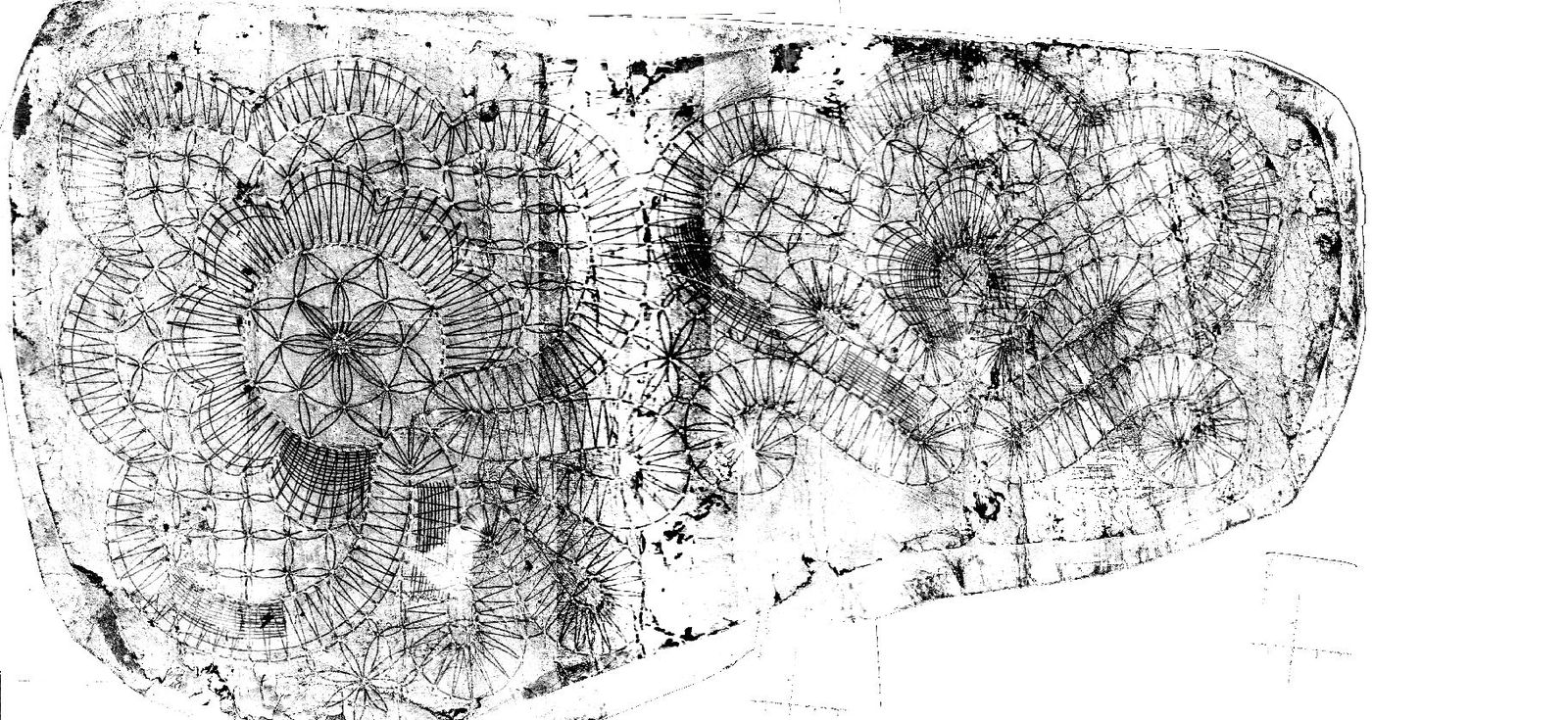

Each bar I have is big enough for two knives, but I cannot simply halve them – there is nearly 10 cm overlap towards the tips. That way I get longer knives whilst wasting less material. I have made a new paper template and here you can see how I laid it on the bar. To draw the outline I covered the whole bar in blue color using very thick (1 cm) marker. A much cheaper and more readily available option to machinist’s blue. You can also see that I have lost my drawing needle somewhere in the 10 square meters of my shop so I have made a new one from an old shuttle bobbin. I hope I won’t lose it too.

When doing this I have wanted to test an idea how to improve my process already, so I have made another template which allowed me to mark not only the two holes for pins, but also a hole at the center of the finger groove. Unfortunately I did not make a picture of that.

But here you can perhaps see why the third hole. After marking the hole positions with a center punch, I proceeded to the drill. But instead of a normal drill bit, I have spanned in it a step drill which allows me to drill holes from 4 to 22 mm. So I drilled 6 mm holes for pins and an 18 mm hole where the finger groove is. That way I do not need to mess around with some improvised way to grind a nice tight radius that I need. This is a big time and hassle saving in itself.

This is also first significant change in design to the prototype that I have given to my mother. She did not exactly complain, but she commented that a deeper finger groove would be more comfortable. So I am making the groove deeper and therefore the handle inevitably skinnier in this part.

I have marked and drilled both halves, then I cut the bar diagonally with an angle grinder. Using an angle grinder I have also cut excess metal on both knives since I live by the rule – if you can cut it, do not grind it. After that I have tried another time-saving measure that I have thought up in my idle time – I have connected both knives with screws through the pin holes. With that I proceeded to the belt grinder to grind the outline of the blades.

It worked very well and I had outlined two knives very quickly, in fact these three steps took a lot less time than I expected – just one hour overall. And I even see big time-saving potentials here:

- For drilling I could make a template for guiding 6 mm drill bit instead of punching the holes for each blade separately. So for next run I will first fish around in my scrap pile if I find a scrap piece of the right shape and size. Then I can stack and drill more pieces in one go. I will lose some time by stacking, but save time drawing and punching. Also next time I will first drill all stacked pieces with a 6 mm drill bit for the finger groove as well. That means changing the bit once, but I think it will be more than made up by the time saved from drawing and punching.

- I can probably stack at least two, maybe even five, pieces before cutting all the excess with the angle grinder. Five pieces would be 9 mm thick, and an angle grinder should be able to grind through that without big trouble and without too much reduction in speed. And I will waste less time per blade by repositioning the piece in the vice for each cut.

- Ditto for the belt grinder. A new 40 grit belt should be able to grind five pieces at once with only marginal reduction in speed. That would also improve reproducibility.

So I am putting this in the “low hanging fruit” basket, since the 30 minutes per blade is significant 10% of my goal time and I estimate I can cut that easily down to half or maybe even less.