Maybe it’s an ‘F-‘, I’m not sure.

Today, I hauled a great big load of steel to the fabricators in Clearfield. [td fab] Over the last decade, I’ve gone to TD with a variety of weird projects, usually providing rough sketches of what I’ve got in mind. They have never disappointed. Well, there was one mis-communication but that was my fault for assuming they’d know that the thick end of a damascus bar is where the tang goes, not the other way around.

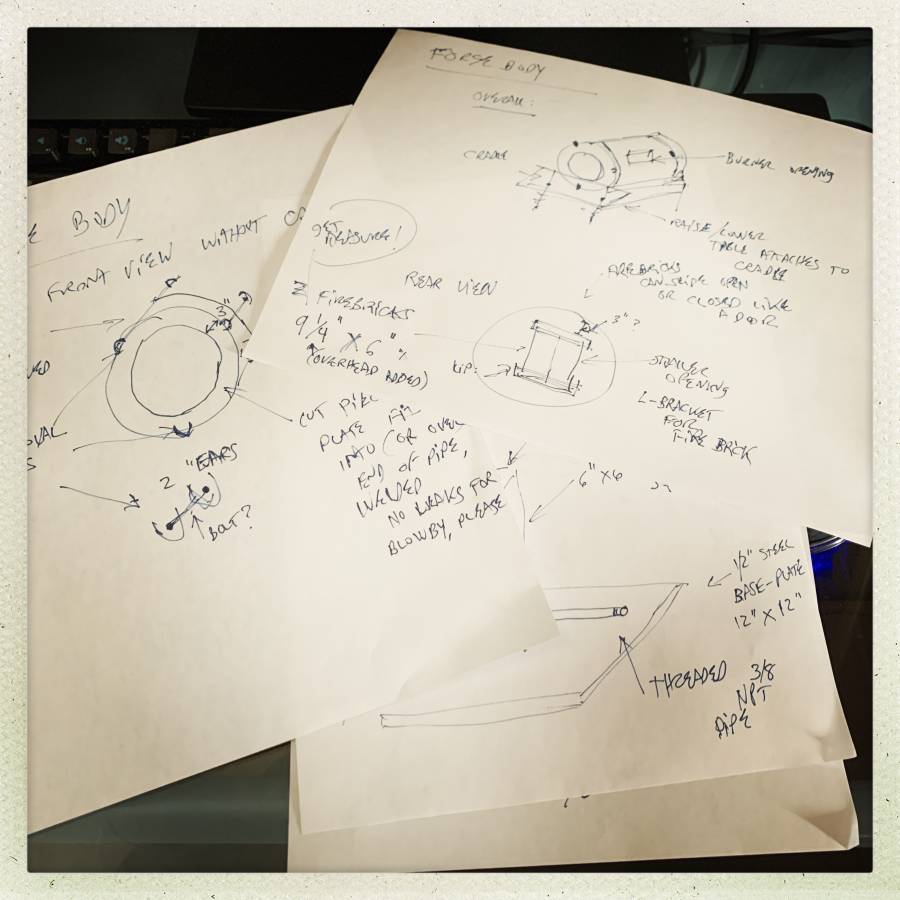

My original agreement with the fellow I usually talk to at TD is “if I don’t specify it exactly that means I don’t care.” So a lot of the details in the work they’ve done for me is based on what they felt would work best. And that’s been fine. But today, I pulled in and talked to The Boss, since the younger fellow I usually work with was away. He took a look at my sketches and started pointing out where I needed to add dimensions. Ugh. Yes, there are a lot of places where I didn’t put dimensions because “I don’t care” is the dimension. But in general, he was right – I have to go back through and specify a few things and maybe do some closer, more detailed sketches of some of the parts. The problem is: I’m a lousy artist. I know I could fire up powerpoint or inkscape and do a really nice design drawing but it would take me days of work. Somewhere, my high school shop teacher, Mr Brune, is spinning in his grave. I know how to do mechanical drawings with all the measures and labels, but I simply do not want to – probably because of Mr Brune’s punctiliousness.

In the meantime, the back of my truck is full of parts for “some assembly required.” About 500lb of parts, in all.

The heaviest single part is the 1/2″ thick 4 x 3-foot steel plate, though the longer piece of pipe comes pretty close. These are actually components for a couple of items: 1) a forge body, 2) a vertical smelter, 3) a vacuum casting machine. Getting the forge assembled is the priority, since when I get it back I am going to need to cast a refractory lining in it and plumb the gas system. The red thing in the right-most piece of pipe is a ribbon burner – it’s a refractory-filled plenum that distributes the burning propane/oxygen mix out to the forge body evenly. That needs to be mounted through an opening cut into the side/top of the pipe, and will provide the heat. My plan is to aim high (I always do) (my friends call it “overkill”) (I have few friends) and build the fire system with a blower fan to drive more air and generate more heat, as well as a K-type thermocouple in a ceramic probe protector, hooked to a programmable temperature controller and a normally closed solenoid valve on the propane line. I recently saw another smith using such a system and it is delightful indeed to be able to set the temperature on “weld” or “quench” and just let the forge’s feedback loop figure it out. I’m going to have to do some careful thinking about failure modes – what happens if the power fails (propane valve closes) and then returns while the body is still hot (“pop!”) or the heat causes combustion in the feed-pipe when the blower drops the pressure – I am going to need a spark arresstor and perhaps a small battery-backed uninterruptible power supply that will allow graceful shutdowns. If you are thinking “Marcus is going to build his very own F-35 of a forge” you’re thinking what I’m thinking but, at least I don’t have to worry about giving it a stealth coating – it’s heat-signature will be a dead giveway.

When I get the forge body back, I’ll need to weld tenons onto the interior so that the castable refractory won’t pull off, then make core inserts and cast a couple layers of refractory. My current plans are to use castolite for an outer layer, with some pearlite added to it to make it more airy and some chopped carbon fiber to make it stronger – then mizzou refractory for an inner 1″ or 1.5″ layer and a cast curved “tray” to sit in the bottom of the forge. I’ll need to make molds for that.

In the meanwhile, the temperature has gone up enough that the snow and ice are melting, which means that in the next 2 weeks I need to get Ken M. to help me move my forging press and then I can get busy on “the great hookuppening” at the new forge building. I need to do the propane feeds, power feeds, and (still) the doors. Ugh! So much work and none if it especially fun. Actually, it is fun, it’s just more fun to have all that stuff done, than to do it.

Well, I can see the TD guy’s point, he wants to make it right the first time so that he knows you’ll be happy with the result and the result will function as planned. I do sympathize over making the detailed drawings, but yeah… I think you should do it. :)

The description of a power outage while using a forge that you have provided is a terrifying thing. I’m not familiar with how the forge works; most of the propane-fired stuff I use keeps working just fine in a power outage. Maybe it’s all hooked in to the electronics, and that’s what causes it to switch off? My oven works like that but won’t come back on when the power returns.

So when you bring all that metal back home, will it be all separated like it is now, or will it have become one big and heavy thing? If so you’ll have to bring it home on a flatbed!

Hi Marcus – combustion controls are kind of my thing these days. If your scavenging-fu is good, I’d suggest looking for a scrapped out old boiler or industrial burner system, they’re chock full of robust and reliable safety features that you could incorporate into your project, and are designed to fail-safe in all use cases. An added bonus would be that they also incorporate a pilot lighting system, so your ribbon burner could be lit-off reliably and automatically with a HV spark and small accessory burner. If you’re using forced draft, they also have an air proving switch that will prevent firing if there’s no air pressure, and will also prevent firing if there’s air pressure when it isn’t expected.

If you can find one that’s drawing NG at the pressure that you’re using Propane, you could also use the gas train, which would have several solenoids, as well as low-gas pressure and high-gas-pressure manual resetting shut off switches. Usually when someone is getting rid of an old boiler, they have no interest in keeping the valuable bits of an otherwise broken system. Our company has literally hundreds of thousands of dollars of old control systems that we’ve held onto while taking the boilers and fired vessels to the scrapyard. Very useful for building new things or repairing old ones. Industrial controls are fiendishly expensive.

If you don’t go this route, consider studying your local gas code for helpful information on the safe design of these systems. If you’re using solenoid valves, a common arrangement is the ‘double block and bleed’ with two Normally Closed solenoids in series with a vent pipe between them that is closed by a NO solenoid when powered. That way any leaking of the solenoid valves is simply vented up and out of the building, rather than possibly building up in your forge. This is a real problem, solenoid valves are not generally considered to be reliable or 100% leak-proof.

Graceful shutdown in the event that you’re constructing your own burner control system is relatively easy. Ensure the system latches into an ‘off’ state on any loss of power and requires manual reset before it fires again – lots of ways to do this.

An couple afterthoughts – using solenoids as shut off valves is only a good idea if you also have some kind of metering valve (like a butterfly) that is also closed on shutoff and gradually opens. If you’re putting out the kind of BTU/hr that you’d need for smelting or forging, it’s probably a good idea to use a slow opening/closing valve for main gas control. Slamming full flow into a hot firebox is going to be a bad idea at all times – if your system dumps an amount of gas in that exceeds the higher explosive limit, and then air mixes into that, you’re going to get what we call ‘puffs’, and the general public calls explosions. They’re unlikely to be catastrophic, but the shockwaves will likely cause deterioration of your refractory and premature failure – also maybe lost eyebrows.

I would strongly suggest trying to find something like a hydramotor valve for this purpose. Not only are they mechanically cool, they provide a positive shut off with gradual opening and closing and complete fail-safe conditions. They’re required by code in many applications, yours might be one of them.

If, as I see in your post, you’re planning on some kind of closed-loop or PID control for this system you’re going to have a lot of starting and stopping of the gas flow unless you’re using a burner with fire rate controls as an option. If you can scavenge a commercial or industrial natural gas boiler, it there’s a good chance of getting a butterfly valve, modulating motor and linkages off of it too. I just pulled a $15K siemens burner control system of of some ‘garbage’ we got paid to remove. Friendly junkyards may be your friend here.

I have nothing so substantial to add but would like to express my envy over you having shop classes where you apparently learned proper drawing. Ever since getting into hobby stuff I have regretted that my school offered no such thing. Ideally I’d love to be able to draw (and write) like an 18th century naturalist but all I can produce is scrawlings I can barely decipher even as I make them. Needless to say, this is none of mine and all of society’s fault. Shoddy education…

snarkhuntr @ 3

I can see that tuning a closed-loop burner heated forge temperature control would be “fun”. I’d guess an underdamped or unstable or othewise badly tuned closed-loop system can fail with a great spectacle.

I wonder if there are specific tools for simulating propane heated forges?

snarkhuntr@#2:

Thank you for the comment. I really appreciate it, since I might have been in the middle of one of those “puffs.”

A couple of things, while I have your attention:

– Typical propane blacksmiths’ forges do not sit pressurized when they are not in use. Usually the tank (outside) goes to a ball valve (inside) that is the master cut-off. That is followed by a pressure regulator (we run around 12psi) and that connects to the burners, which are usually on the other side of another ball valve. When the forge is lit, manually, the ball valve at the burner is opened manually, so perhaps it’s “semi slow-open”

– The forge is usually lit by putting a paper towel in the body, setting it on fire, then opening the ball valve while standing away from the opening.

– The system I was planning to build would have all electrical components on the other side of a magnetic shop switch with an emergency button. Since the gas solenoid is going to be NC, that seems to be a reasonable safety. It does mean that if the power drops, or I turned the system off without stepping down the pressure at the master regulator, there would still be pressure in the line. But it wouldn’t be much and if it bled out into the forge body over the next day or 2 that’s probably no big deal.

– I could put a ball valve on the line between the master regulator and the forge that would let me de-pressurize the whole thing at the end of a session, but I worry that I might forget to close that valve and then I have a big mess.

– I did some research on slow open gas valves and – sure enough – they are normally present in hot water heaters and gas stoves. There are lots of them in the $100 range on amazon.com and they mostly take 1/2″ NPT. My system is 3/8 NPT so that’s just a matter of some adapters here and there. The stove slow open valves seem to mostly run on 12VAC which is also no big deal, it just means the controller board will need to have a transformer on it.

– When I say “controller board” I mean it: this stuff will mostly be screwed to a plywood board attached under the table where the forge sits. The whole table is steel with a composite cement board and fire-brick top. If there is a fire it is designed to have fire on it, after all. I’m going to try to keep that from happening but I’m also ready and the master propane cut-off is off-axis from the whole thing where I can reach it easily. But honestly if something goes wrong I will run outside of the building (I assume explosion would be inside the building) and cut the pressure off at the tank with the tank’s master valve.

The propane system will dump propane into a small(ish) jet – probably a copper MIG welder tip threaded into the interior of a 2″ steel pipe that carries the air from the blower. I plan to put a check valve between that pipe and the blower, The other end of that pipe connects to the ribbon burner that protrudes inside the forge body. There is a small plenum above the ribbon burner where the air and propane will mix some, and it’ll also mix in the pipe. I have never heard of problems with such an arrangement but my pipe will be wrapped with fiberglass and kevlar for insulation and shock absorbtion. That part of the system will not hold pressure. In operation, I planned to have the blower running all the time, so I don’t expect gas build-up in that pipe unless there is a power failure, but even then if the forge is hot that stuff will bleed pretty quickly into the forge body. Which makes me think there maybe should be a check valve on that pipe between the ribbon burner and the jet.

Any feedback you have would be great. Before your comment@#2 I had no idea there were slow-open solenoids and now I do. There are probably other things I don’t know about.

Ice Swimmer@#5:

I wonder if there are specific tools for simulating propane heated forges?

Blacksmiths don’t test things that way. There’s a lot of: “put it in the parking lot on a small propane tank, power it up and see what happens.”

komarov@#4:

I have nothing so substantial to add but would like to express my envy over you having shop classes where you apparently learned proper drawing. Ever since getting into hobby stuff I have regretted that my school offered no such thing. Ideally I’d love to be able to draw (and write) like an 18th century naturalist but all I can produce is scrawlings I can barely decipher even as I make them.

It was miserable, at the time. We had to learn how to write a different font and everything. This was the 70s and we didn’t have electronic calculators, so when we needed to do a line on something that was going to be 3″ long (in reality) on a 1:3 scale drawing, we had to scale it. OK, that one is easy, but the 1/8″ items were less fun. One of the worst things was that Mr Brune expected us to figure out the right scale for our drawing so it would fit perfectly on the page and still be reasonable to calculate. There were times when I ran out of paper and silently wept at the table. But, practice makes perfect: each time you do the same drawing the better it gets.

A mechanical drawing of a pancake flipper, for a high school student, was a day-long ordeal.

I am pretty sure you could find some old textbooks on ebay, and teach yourself to get the look from them.

https://www.ebay.com/itm/Visualized-Basic-Mechanical-Drawing-by-Almon-Joseph-1961-Textbook/193863305875?hash=item2d23274a93:g:MdMAAOSwx1tgDl7A

That looks a lot like our old textbook. I feel a creeping dread when I see it, so that may be the one.

Hi Marcus,

In the world of industrial controls, you generally design the system with the assumption that if there is a way that a user can screw up operations, they will. How you choose to build your forge will have to be determined by the level of trust that you have in yourself, and anyone else you allow to run the equipment.

With that caveat, I don’t think there’s much inherently wrong with the setup you’ve described. I would interlock the final gas valves with an air proving switch (usually a diaphragm switch) rated at something like 80% of the expected blower head pressure, so that in the event that airflow stops for some reason (like your blower eats a rag), the gas stops immediately. The reason being is that your pipe and burner body will contain a more-or-less flammable mixture of gas and air, and the only thing stopping the flamefront from coming back up the passages in your ribbon burner is the pressure and flow of the gasses coming in. In the event that air stops, combustion will back up into the burner (not neccessarily a huge problem) and eat up the air. Then the incoming gas will start to fill into the hot chamber, and may or may not light off on it in an unpredictable fashion.

You may also benefit from adding some turbulence where you inject the propane into the burner tubing. A couple of baffles or something to increase the mixing of the fuel and primary combustion air.

Setting up a latching relay on the blower/gas start button should be trivial at whatever controls voltage you end up using, that way your system cannot restart unexpectedly following a loss of power or the deployment of the e-stop (if you set the estop to cut off all power, including to the latch).

The boiler components would be more useful if you intended to create a self-cycling or restarting forge/furnace capable of modulating its temperature automatically. What occurred to me today is that there’s a much simpler way to do this, though it would require some trial and error. If I ever get far enough down my projects list to build the forge/furnace of my dreams, this is likely what I’ll do:

Incorporate at least two ribbon burners into the design, all fed from a common (and oversized) blower with dampers on each to allow adjustment of airflow and butterfly valves to start/stop the flow to them. This needs to be sized so that the blower is producing its maximum static pressure even with all three burners at full open, or the combustion controls get far more complicated.

Size the ribbon burners so that there is one primary ‘baseload’ burner that will maintain heat in the chamber, or allow it to slowly fall. Then you can use a PID controller to start/stop the larger burner(s) to modulate the temperature which is monitored with an appropriately rated thermocouple. If the burners are correctly oriented, the baseload burner can light-off the secondary burners without a risk of explosion.

If possible, I’d also incorporate a take-off tube, air or water cooled, that allows a sample of the chamber atmosphere to be routed via a lambda sensor, so that I could automatically adjust for an oxidizing or reducing environment as required.

Honestly though, I’d probably spend more time designing and building such a tool than actually using it. Not that this has stopped me before – most of my hobbies seem to end up just building tools that I could use to build final objects, but mainly use to make more tools.

Ice Swimmer @ 5

I’m not sure that underdamping would be a big problem here. Given the large DeltaT to the environment, the system would seem pretty responsive to a loss of heat input, I doubt there’d be a ton of inertia once the burner turns off – it should start to drop pretty fast. Hence the suggestion above of using multiple burners. A poorly tuned controller trying to maintain a specific heat with just one burner is going to be trying to rapid-fire the thing in ways that seem suboptimal.