Once I had the blade in its final shape, and etched, I stopped sending images of what it looked like to its future owner. Opening a box with a new knife in it should be a surprise, and a small voyage of discovery. It’s especially a surprise if the person didn’t expect a knife and jams their hand into the box to see what’s inside; my sister finally forgave me for sending her an unexpected paring knife many moons ago.

The blade sat on the bench, silently reproaching me while I tried various things for the handle. I made a sculpey master of the cap, with a fish-shape, then did a plaster investment mold from that, and cast silver in it – and it turned out really ugly. I spent a while messing with Blender, doing various renderings that I thought I might have 3D printed in silver. I was not happy with any of these things and I don’t even want to think about them any more. Finally, I emailed the client that I was just going to finish the knife off plain and simple and that I lack the soul of an artist.*

Plain and simple, then. For that, you can’t do better than a nice thick chunk of fine silver:

That’s an hour with a jeweler’s saw, and some clean-up on the belt sander, then an hour or two making the hole through the silver fit as closely as possible to the tang of the blade. This is the weakest part of my process, I admit – my tangs are never geometrically even-shaped, and sometimes they are not evenly tapered, which means that there are tiny little gaps between the blade and the bolster. When I see the work of master bladesmiths, who get that fit micrometer-accurate, I cringe a little bit, and mutter things about “soulless perfection” that I don’t really mean.

Then, I drill a hole in the end-cap and thread it (10/32 tap) and grind the end of the tang down to the right diameter by simply rotating it and eyeballing it, then run it through a die to thread it, too. Measuring the distance between the bolster and the cap gives me the length of the handle wood and it’s off to the table-saw with a block of bog oak and my Mitotuyo micrometer. From there, to the drill press to make a hole through the block, and back to the vise where the hole is adjusted to fit the tapered tang by the simple expedient of 45 minutes of filing and sawing with a broaching tool. Some knifemakers have really nice broaching tools; I use a sawz-all blade that I’ve ground down to about 1/4″(5mm) width, the end of which is epoxied into a golf ball (aka: “handle”) with a hole drilled in it. By the way, if you don’t know that trick: used golf balls are very cheap on Ebay or at a golf course, and make great field expedient handles for many purposes. That’s a trick I learned from my grandfather, whose entire violin-making tool kit featured golf balls in many forms including the old gutta-percha ones.

For reasons I do not fully understand, I usually do my handle glue-ups on my kitchen counter. I also do my etching in my kitchen sink. To get the final blade etch, I watched it closely and pulled it from the chemicals when it was at the moment of best contrast.

Once the handle is filled with epoxy and everything is tight and cured, it’s ready for the handle to be shaped. The blade gets wrapped in parchment paper and then gaffer tape; at this point I don’t want anything to scratch it, and also it’s getting kind of sharp and the only thing I’ll have to hold onto is the blade, since I’ll be shaping the handle.

I’ve learned to strategize the handle. You can’t just start removing wood or you’ll wind up hammering the whole thing to bits and starting over. My plan with this one is to use the big 6″ belt sander to set up a taper between the bolster and the cap, then I’ll take a deep breath and figure out what’s next.

When it got to this point, I was thinking “that’s not bad!” except it’s mighty chunky and this is going to be a stocking-top knife. It needs to be thinner side-to-side by a goodly bit. By now the sanding belt is contacting the silver, which is problematic because it heats up ridiculously fast. I have no idea why – perhaps one of you physicists could tell us something? – but silver seems to heat up faster than steel and (obviously) faster than wood, which is an insulator by comparison. If you don’t pause frequently, the epoxy holding the bolster from slithering around is going to melt. Usually in this case I keep a spray bottle of methanol handy that I can spritz the metal with to cool it if I’m impatient.

Now, I have a problem: I want a kind of lobular “traditional” shape but the only way to get it is to just grind away and make it all work out somehow. After coming this far, “just fudge it” is the last thing I want to be doing, but that’s how it’s got to be.

Bog oak is really tough stuff, so it’s slow going. That’s actually comforting since it means I won’t be able to screw up as quickly. If I were using my blade-grinder with a low grit belt, that would take less than a second. The big sander lets me do even planes, and its belts are not very aggressive, so I have lots of time to think and strategize and fudge around and balance everything and stop and look at it while the silver cools.

It’s starting to get there, wherever “there” is. And, right as it’s getting there, I hit a pit in the bog oak. See it, there right dead center of the handle from the camera’s perspective? One possibility is that I’ve ground into where the tang goes, but it doesn’t look quite like that. I have choices – leave it or grind it out. I take it to the vise and carefully clean it up with a wood rasp; the pit is not very deep and I can resume breathing. From there, it’s final shaping with the wood rasp, then rough sanding with sandpaper wrapped around the rasp, then successively finer sandpapers and finally hand sanding.

The knife is done.

It’s basically “sharp” already, but I amuse myself by sharpening it frickin’ more because it’s supposed to be a hold-out weapon and that means it’s got to be able to cut woolens. Joking aside, I’ve heard stories that people say you shouldn’t take a sgian dubh out of its sheath without it tasting blood, so I may as well make that as easy to get as possible. By the way, that appears to be a generic legend; I’ve heard it about Japanese swords as well, which is nonsense because why ruin the polish with unnecessary salty blood?

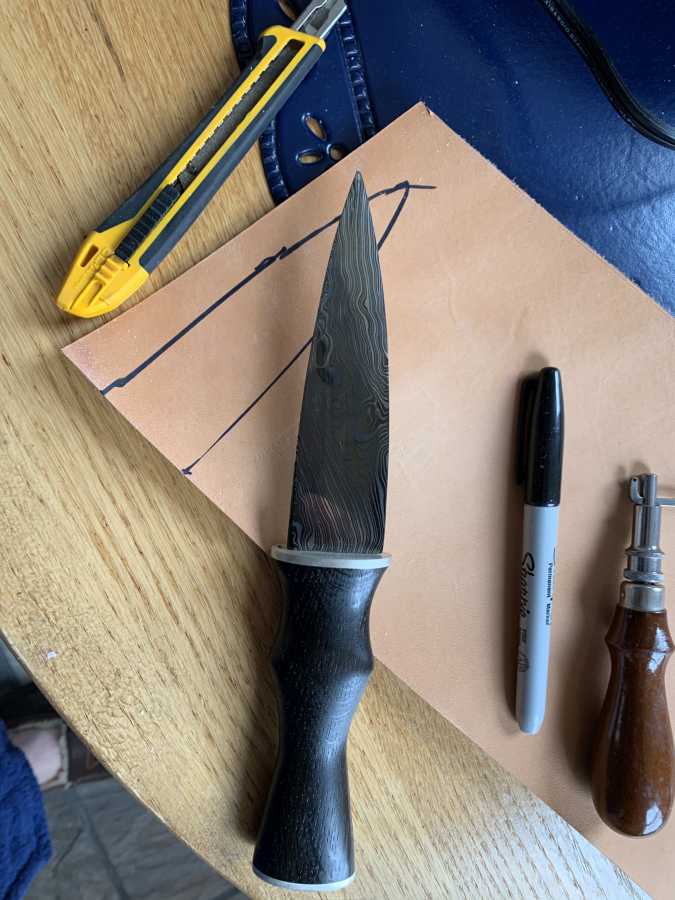

Sheath-making is not my forte, though I used to do a lot of leather-work and have a pretty good sewing machine with a walking foot. I just don’t do it enough to be good at it. But I assemble the materials and start laying out the pattern:

Basic sheath 101 has a gusset that keeps the blade out of the stitches, and two sides that are stitched together through the gusset. I had all the pieces cut out and something interrupted me and I left it all sitting on the kitchen table for a couple days. Then, while I was dozing, I thought about the mackerel and that gave me an idea: what if I cut the shape of the fish through the sheath and positioned it to take advantage of the watering of the blade?

The incised scribe-lines are guides for sewing. Now, I have to admit something painful, here – the sheath above got destroyed when I stitched it. There was a loose fiber in the poly thread in my sewing machine and it caught and pulled the foot sideways and the stitch-line went right off the side of the sheath, completely ruining it. That was just a sign from the knife gods that I hadn’t gotten it right, and I needed to do it better. I like the picture, though. It took me about 20 minutes, each time, carefully carving away leather with a #11 scalpel blade.

Everything gets a wipe with wax, then wrapped up separately and dropped into the gentle clutches of the USPS. The USPS, by the way, does not think Scotland exists. There’s “Great Britain” and “United Kingdom” but Ireland exists and Scotland does not. Inevitably this leads to a question at the local branch office, as they try to figure out what the zip code means because it’s not in England, per se. The software in the Post Office’s mini scales has to be some of the worst I’ve ever encountered (it doesn’t even keep a running total, and the post officer has to add the tab up on a hand calculator) – it always takes a few minutes to get a package shipped to anyplace other than the US. Because we’re #1!

It got there OK, two days faster than a turned ashwood bowl I sent to someone in England proper two weeks before I sent the knife. COVID has crippled the postal services of the world.

* Soul of an artist: technically, I did have the soul of an artist but someone scuffed the chalk on the pentagram and the darned thing escaped and took up residence in my hammer.

For your information: please don’t store a nice knife in leather long-term. My favorite storage is to wrap things in clean dry felt with a spritz of WD-40 or if it’s a blade in the Japanese tradition, I use camellia oil (the traditional oil for katana blades). And please ignore that nonsense about anyone saying “it must taste blood before you put it away!” – here’s how: “We have a tradition around here that anyone who says that has to donate the blood.”

For an end cap it wouldn’t be unusual for me to cut the tang short, then put a 1/4″ silver rod through the end-cap and sink that into the other end of the handle with epoxy. It looks pretty snappy, that way. But since this knife had a kind of tradition-y look to it and was commissioned for a traditional purpose, I thought that having a little spud of twist damascus at the end cap would be pleasingly old school. I don’t know. I make those decisions on instinct. I have a theory about that, which I ought to do a posting about for some future Sunday Sermon.

Oak, even bog oak, is pretty porous. I rubbed a drop of Birchwood Casey Tru-oil on the handle every day for 2 weeks while I psyched myself up to do the sheath.

Ooooh – that looks very nice! I wouldn’t mind pulling that out of my hose.

Very Beautiful!

I do have a question: Why do you spray the metal with methanol? Shouldn’t ethanol do the same job for much less toxicity?

For heating up: silver has about the highest heat transmission rates of all the metals, so it heats up really uniformly (and quickly. It is a smallr piece, so not much thermal mass to distribute the heat to.)

It’s absolutely amazing. I love the mackerel idea and the effect works nicely.

I remember hearing that “taste blood” bit about kukris back in the 80s/90s, and it sounded suspect to me at the time…

That really is a beautiful wee knife!

It’s just a poetic way of saying “this isn’t a toy, don’t take it out just to play with it as there is a risk of injury”. Something many gun owners could use getting their heads around…

What about the one that you should always give at least a token payment for a knife given as a gift, or the blade may sever the friendship? It’s a fairly common superstition amongst knifemakers and users over here, but I don’t know if it’s more widespread…

Negative fish! Cool!

Silver is in the same group as copper, whose specific heat capacity is pretty low….

Yup: Copper, Iron, Steel all at ~400J/K

Yowza: Silver: 235J/K

WTF? Gold: 129J/K

I didn’t expect the silver to be *that* low, and Gold (also same group) is as far below again.

It looks very beautiful.

Yep, those can be “fun.” The good news for me is that computers acknowledge the existence of Latvia. The bad news is that automated systems always ask me for “state/province/region.” We don’t have those in Latvia. In my case, in my address there’s only my city and postal code.

Beautiful work! I like the curves of the handle — you have a good eye for a gracefully shaped rear part.

lurker753 @ #6:

That’s 400 J / (kg K), not 400 J / K — the specific heat is the amount of energy it takes to rise the temperature of one kilogram of material by one kelvin (or degree Celsius). The kilogram there is a clue to what is going on. If you look at energy per volume, or even per mole, metals are much more similar. Gold is about twice as dense as silver, and stores half the energy per unit of mass, but that works out to roughly the same amount of energy per unit of volume. Take aluminum: at about 900 J / (kg K), but with a density about a third of that of iron, it’s in the same ballpark for volumetric heat capacity. It’s even closer when you take molar heat capacity, with most metals at around 25-26 J / (mol K), from lithium (24.8) to uranium (27.7). The only notable exception is beryllium (16.4 J / (mol K)). So each atom in a metal can store about the same amount of energy regardless of its type, and most variation is explained by their different atomic masses.

What a gorgeous little knife! I love the mackerel, nifty.

The post office in the UK has a whole load of peculiarities around addresses, the main one is that regardless of how things have changed since, and they have, you are considered to be in the county your area was in when post codes were introduced. This means that a far as they are concerned I live in Cheshire despite Stockport having been part of Greater Manchester Metropolitan Authority etc since 1974.

avalus@#2:

I do have a question: Why do you spray the metal with methanol? Shouldn’t ethanol do the same job for much less toxicity?

In Quaker state Pennsylvania, distilled spirits are tightly regulated. When I was doing wet plate photography, I applied for a license for ethanol as a process chemical, which was immediately denied. The best I could do for ethanol was to smuggle cases of Everclear up from Maryland, a 4 hour drive.

I use alcohol because I don’t want to raise the grain of the wood or rust the metal. I believe that rust will form faster on hot steel. Mostly, I just wait and let it cool but if it gets too hot I give it a spritz. I assume, however, that the latent heat of evaporation for various alcohols is lower than water. Medical isopropyl has water in it, so it causes rapid rust.

lochaber@#4:

I remember hearing that “taste blood” bit about kukris back in the 80s/90s, and it sounded suspect to me at the time…

Yeah! Me too! But I never checked up on it. Darn, I actually knew another kid who knew a Gurkha and I could have asked, had I dared. [One of my dad’s acquaintances was a British officer whose former Gurkha sergeant became his kids’ nanny. Now, just think that scenario through…]

lurker753@#6:

Yowza: Silver: 235J/K

WTF? Gold: 129J/K

So it doesn’t track with weight? If Aluminum is in the same range as steel, and gold heats up very easily, it’s not because thermal mass tracks with actual mass, if I have that right.

Sorry Marcus, yes it tracks with weight. As cvoinescu@6 pointed out, I goofed on the units. J/kg.K, not J/K.

So, 385J to heat 1kg of copper by 1K.

So 20W of sanding heat into 20g of silver would mean 4.25K increase *per* *second*, from room temp to yowch in ~10secs.

(There’s also something else going on: when you sand a thermal insulator, heat doesn’t flow away from the worked zone, so each stroke removes much of the heat left from the previous one. Small meteorites are super-cold when they hit the ground – ablation in the upper atmosphere vapourises the surface faster than heat penetrates, so when it slows to terminal velocity, the remaining material is still cold. A copper/silver/gold meteorite would probably be molten.)

Beautiful work.

That is a gorgeous knife. I love the fish idea in the sheath.

I find it ludicrous that it is easier for you to buy methanol (which is highly toxic and can enter the body through the skin and by vapor easily in big enough dose to cause trouble) than denatured alcohol which cannot be drunk but is safe on contact with skin. Seriously, many laws around the world just make no fricking sense whatsoever. I do get why alcohol needs to be regulated, but that is why denatured alcohol was invented, so craftsmen still can use it. Around here the situation is exactly reverse – denatured ethanol is cheap and readily available, but methanol you can only get with a special permit.

Honestly, I would not touch methanol with a 10 foot pole, that stuff is nasty.

I’ll go get a big can of denatured alcohol next time I am at the store.

Marcus: Thanks for the explanation. Sorry if this is mean … but that is such an “american” explanation. Other than that, I absolutly double what Charly said. I have to use Meth in the lab, but I really take precautions for it. Especially no vaporizing it outside the fume hood! Please do get denat. Alcohol, your organs will thank you! If it has to be really water free throw some baked mesh 4A molesive in it.

lurker573: Yeah, what cvoinescu said. The mole is a sneaky beast of a unit XD.

Man smithing brings so many material scienences together!

Charly@#15:

I find it ludicrous that it is easier for you to buy methanol (which is highly toxic and can enter the body through the skin and by vapor easily in big enough dose to cause trouble) than denatured alcohol which cannot be drunk but is safe on contact with skin.

You can’t buy marijuana in Pennsylvania but they kept the gun stores open as “critical facilities” during the lockdown. They closed the wine stores (hard liquor) but you could buy beer at wholesale distributors. As I have mentioned elsewhere, I could not buy ethanol in bulk (not even denatured) but I could buy kilos of potassium cyanide and ether, and concentrated nitric acid – which FEDEX lost in shipment. 6l of concentrated nitric acid. Riddle me that, batman.

It takes the imagination of a sci-fi writer to extrapolate how messed-up the US is. With regard to hazardous substances – you can buy just about any chemical as long as you have a credit card. Because credit cards are proof of identity, or something, and the US system is based around not stopping people from doing horrible things, but knowing how to punish if something goes wrong. Once you give up on looking for rhyme or reason, it makes sense. Oh, here’s another one: the Boston Marathon bombers used perchlorate/aluminum from fireworks to make the bombs, I assume because they never realized that you can buy 5lb of FFG black powder at WAL-MART (because: guns) at a shot. If you buy more than that, you have to go put it in your car and come back in and buy another 5lb. The US system was designed by stupid people, for stupid people.

Nice job! Took more patience than I possess, that’s for sure. Makes me wonder how many smith-hours it took to supply swords for a Roman legion.

The knife is gorgeous and I love the fish cut-out in the sheath. What a great idea! I think that’s really creative.

Yes, silver gets very hot very fast. I rigged up a horse IV bag that I got from a vet… I think it holds a liter, maybe more, I can not remember, and set it up so it would drip at the required rate on my work as I carved it with a Foredom. That’s pretty cheap to do and of course you can have most liquids in it although I always used water. I did not have the worry of rust.

When polishing sterling silver at the polishing wheel I always wear gloves and pay very strict attention; if the leather starts to smoke, it’s too late and I’m going to get burned. I work next to a deep sink for this very reason: I can easily get to water very quickly and cool things down. I also keep a small pan of water under my polishing wheel and that brings some moisture into the air and helps things stay a little cooler than they might otherwise. Basically though I don’t do too much at a time. I stop frequently to cool the metal. It only takes a second or two to cool it down and then I can keep going; I don’t even have to turn the wheel off.

Did he know this joke? (Trad British Army joke about those guys…)

The Gurkha CO is being briefed on an upcoming mission. The REMF in charge is explaining how the men will be flown in behind enemy lines at night, to be dropped over the target area from 200ft. The Gurkha commander shakes his head. “We can’t do it. We must jump from 100ft.”

The REMFs look concerned and say “But Major, if we drop your men from 100ft, their parachutes won’t have time to open.”

CO brightens up. “Oh… we get parachutes? Carry on.”

Ooh, that looks cool. I like that handle shape (i might copy it, if i don’t get distracted by other projects).

isn’t there a traditional way to get high proof ethanol in the backwoods of Pennsylvania? you just needs some corn and someone who knows metalwork :P

how is wine hard liquor? you can easily make beer stronger than most wine

Watch This Two-Armed Robot Carve Like a Renaissance Master